DCS vs PLC - what are the key differences?

This is one of the most commonly asked questions in relation to industrial control and automation systems (ICAS). In order to answer this query properly, we need to dig briefly into the history of these two systems and take a look at their internal components. On a basic level, Programmable Logic Controllers (PLCs) control individual machines, systems, or devices while a Distributed Control System (DCS) manages multiple machines throughout an entire factory, plant, or manufacturing works.

A DCS, as its name suggests, is a control method which mostly utilises independent central processing units (CPUs). Each CPU is in charge of controlling individual parts of the process so that if one fails, the other CPUs will continue performing their functions without interrupting the overall system.

PLCs on the other hand are mostly used for centralised control. This means that a single PLC will control the whole process. Because a PLC works on a centralised mechanism, the PLC controller and all associated operation is linked to that controller. The main drawback of this type of system is that if the PLC fails, all associated operations will stop whereas a DCS has systems in place to mitigate this risk. In relation to cyber security, if a PLC is infiltrated, a threat actor can potentially wreak havoc across an entire system controlled by the PLC. As a result, new technology is beginning to emerge, focusing in on antiquated authentication procedures often inherent in these systems.

History of DCS and PLCs

The primary goal of early PLCs was to replace traditional controls systems, something akin to relay rooms found from 1960 onwards. These old systems were made entirely of relays and contractors and were notoriously difficult too manage. Contractors would often refer to diagnosis taking ‘five hours to find, five minutes to fix’ in these systems. DCS came onto the scene a few years later in the early 1970s, not to replace PLCs, but to fulfil other requirements emerging within the automation industry. This means PLC and DCS have coexisted for many years across different applications, with both having their own pros on cons depending on the application.

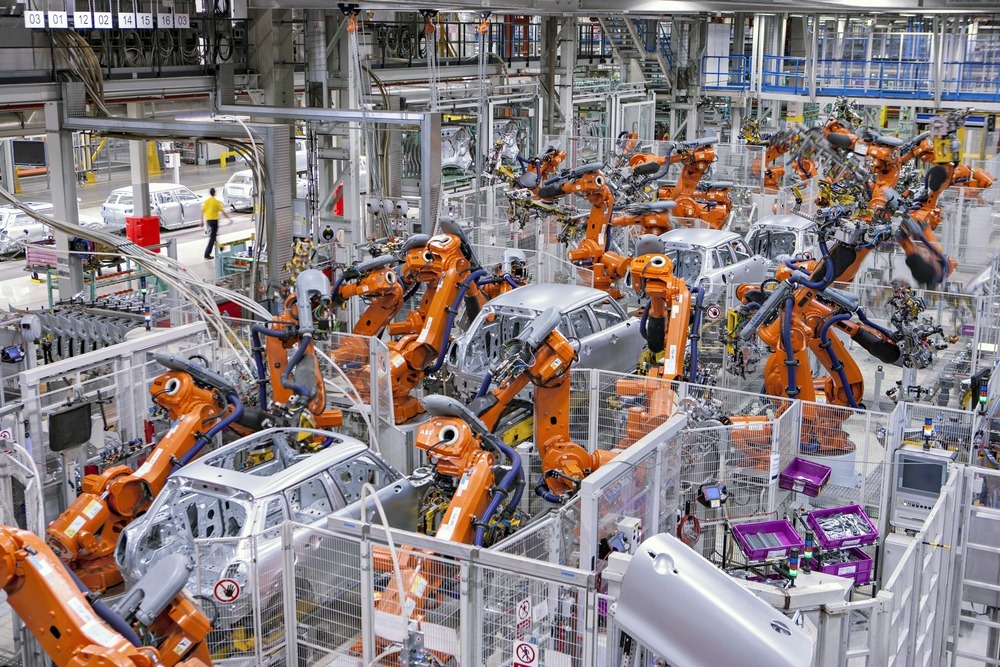

Although modern PLCs are advanced compared to their early counterparts, they are most commonly found in discrete process automation or discrete control. Discrete control includes applications where the inputs and outputs have a limited number of conditions, usually two but sometimes more, for example on/off, true/false, open/close, or 0/1. The automobile assembly line is a good example which mostly utilises digital signals and limited analog signals.

Modernisation and DCS

DCS is more appropriate for continuous processes which include multiple analog signals and more complex Proportional Integral Derivative (PID) control loops which can be found in power plant and refinery settings. This also means that DCS reaction time and/or scan cycle time can be considerable compared to that of PLCs due to the heavy processing requirements of the systems they operate. In addition, a DCS will also often apply high-level programming languages including Continuous Function Chart (CFC). These languages are very useful for more complex programming, monitoring, and engineering actions that require lots of predefined functions, however they also generate substantial code after being compiled resulting in considerable burden for CPUs. This can often result in slow response time to critical inputs within the system. PLCs on the other hand often utilise low-level programming languages including Function Block Diagram (FBD), Structured Text (STL) or Ladder Logic (LAD). The generated code with these languages is substantially less and are more in-line with the machine language itself. This is why PLCs are often used to cover back-up systems which need to be enacted quickly.

Difference in monitoring systems

Another key difference can be found by looking at the monitoring systems. In a DCS, there is a integrated software package which encompasses a complete set of monitoring facilities. In PLC systems however, there is usually no relationship between the programming and monitoring environments, with these often needing to be designed and developed by the client. This is often why PLC systems are often referred to as a ‘blank slate’ with open architecture while DCS’s are more akin to turnkey solutions, the latter often developed and sold as a complete off-the-shelf system, ready to be implemented.

Pros and cons vary between the two

Overall DCS’s are more reliable in comparison to PLC systems. This is not just because they are distributed and/or decentralised, but also because they are redundant on multiple levels. Redundant engineering is designed to improve a systems reliability by using back-up processors in the event of primary process failure. This is important for two key reasons. Firstly, many DCSs control safety-critical processes in which failure or outage of equipment could result in injury or loss of life. In addition, redundancy also increases equipment reliability, leaving the DCS operative to concentrate on displays, software, and applications. These redundant levels include CPUs, power supplies, servers, network switches and network cables, all of which can be controlled separately in the event of system failure.

In addition, as DCS response times are much higher when compared to PLC, DCS is best utilised for processes with more analog signals and PID loops. PLCs on the other hand are better for processes which require more discrete signals and less analog signals.

With a DCS, operators benefit from numerous predefined functions and function blocks and high-level programming languages, but in PLCs you often have to write and define the functions yourself. In addition, the network architecture of the DCS is easier to implement utilising an integrated hardware and software package. However, DCS hardware and software package cost a lot more than their PLC equivalents and are often much less flexible. DCS systems can be summarised as highly optimised and stable, but with limited extensibility while PLCs, despite being less stable and requiring more effort, come with much better flexibility which suits certain industries. This is why PLCs remain an integral part of industrial control systems (ICS) regardless of whether they are used as part of a centralised or decentralised system.

--------------------

swIDch will continue its quest to innovate and pioneer next-generation authentication solutions. To stay up-to-date with the latest trends sign up to our newsletter and check out our latest solutions.

The ubiquity of Public Key Infrastructure (PKI) in securing our digital world is undeniable. From the padlock icon in

When people think of cyberattacks, they often picture stolen data, financial fraud, or personal privacy violations.

In the realm of Operational Technology (OT), the security measures applied to protect critical infrastructure systems

Looking to stay up-to-date with our latest news?